Circular Apparel

Circular Apparel Policy Innovation Lab (CAPIL)

Project Overview

CRB is leading an initiative titled the Circular Apparel Policy Innovation Lab (CAPIL) that is funded by the Laudes Foundation. CRB is supported by Intellecap and Fashion for Good in CAPIL. CAPIL has been set up with the objective to explore and suggest policy interventions required for enabling a circular economy transition in the textile and apparel sector in India.Globally, there is considerable momentum towards circular apparel, led by international brands. This offers an opportunity for Indian apparel suppliers/manufacturers, by demonstrating transition towards circularity. An inclusive policy process to trigger circular innovation/initiatives in the textile and apparel sector in India will strategically align to the Indian government’s strong focus on resource efficiency and circular economy. There is also a need to establish a mechanism that links ground-level industry issues/realities to policy to facilitate the adoption of circular economy practices in the Indian textile and apparel sector.

Given the complexity of the subject, effective policymaking and implementation of circular economy also requires coordination between relevant government organs viz. central government, sectoral/line ministries, central and state departments.CAPIL would contribute towards well-informed policies and implementation mechanics to support transition towards circular apparel in India, by bringing various stakeholders under one umbrella and provide evidence-based policy input.

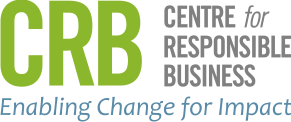

CRB has created a framework on circular apparel to understand the various aspects of the textile and apparel value chain where circular economy can make a difference. The framework helps capture input from stakeholders from the sector, mainly on the priority areas in each A&T cluster/region in India. The vertical axis lists the Circular Economy focus areas, and the horizontal axis shows the A&T value chain (cotton, in this case). Given below is a snapshot of priorities (cumulative) captured by CRB through stakeholder consultations in clusters like Ahemdabad, Vadodara, Panipat, Bengaluru, Tirupur, etc.

Objectives

The project activities would be implemented with the following objectives

- To understand the priority areas for intervention in the textile sector for circular economy transitions

- To collect input for policy that would make such transition to Circular Apparel possible

- To create active stakeholder groups in selected textile clusters to sustain the momentum on circular apparel and to continue engagement with policy makers.

Anticipated Outcomes

- Better awareness among stakeholders about the benefits of circularity in their value chains

- Active conversation in the policy space about circular economy in textiles (government and corporate policy)

- Policy briefs prepared for individual clusters/state governments

Events

Workshop on ‘Role of policy in promoting a circular & inclusive textile & apparel sector’, 17th September, 2020

CRB held a national-level workshop on how public policy can enable and accelerate circular economy transition in the apparel and textile industry in India, in partnership with Circular Apparel Innovation Factory (CAIF) & Fashion For Good & supported by Laudes Foundation. Findings on cluster-level challenges to circularity, their solutions and relevant policy support were presented, followed by a panel discussion by representatives from the Government as well as industry experts. Need for R&D, industry benchmarking, shared responsibility and accounting for embedded natural resources emerged as some of the important themes.

Workshop on 'Circular economy: Strategy for green and inclusive recovery for Tamil Nadu’s Textile and Apparel clusters', 21st August 2020

CRB, along with Circular Apparel Innovation Factory (CAIF) & Fashion For Good held this workshop to solicit inputs from stakeholders from the apparel and textile sector in Tamil Nadu, on priority issues and solutions required for a transition towards circular economy. Policy intervention ideas were also discussed, which could help a sector-wide transition in the state. The workshop was attended by manufacturers, innovators, brands, and government agencies from Tirupur, Coimbatore, Karur, etc.

Workshop on Circular Economy in Karnataka's Textile & Apparel sector

CRB organized a half-day workshop on Circular Economy in Karnataka’s Textile and Apparel sector on 19th February 2020 in Bengaluru, in association with Intellecap and Fashion for Good. The workshop saw participation from spinning mills, brands, start-ups, apparel manufacturers and the state government.

CRB ISS2019 Session on Circular Apparel & Textiles

A plenary session on circular apparel was organized at CRB’s annual conference “India and Sustainability Standards 2019”. Speakers from renowned brands, entrepreneurs, and academia had participated. The panel discussed issues ranging from fast fashion, sustainable fabrics, to decent working conditions and productivity management.

Circular Apparel Policy Stakeholder Consultation

A stakeholder consultation was held at IIM Ahmedabad Campus, Gujarat on 22 October 2019 to gather input on circular apparel policy priorities in Ahmedabad, Surat and Vadodara textile and apparel clusters. Representatives from academia, industry, and Gujarat government (Gujarat Cleaner Production Centre, Industries Commissionerate) had participated.

Reports

Case Study

For further information, please contact

Ms. Devyani Hari

Director (Programmes)

Email: devyani@c4rb.in

Phone: +91 (11) 41088853

Mr Ramanuj Mitra

Programme Officer

Email: ramanuj@c4rb.in

Phone: +91 (11) 41088853